Conveyor Safety Switches

Discover the Belt Misalignment Switch, and the Safety Cable Pull Switch, among others for Material Handling operations.

Belt Misalignment Switch

High level detector in bins and vessels containing a wide variety of materials.

This belt misalignment switch is used to monitor the position and tracking of conveyor belts. It is mounted on the conveyor structure and adjusted so the roller arm is the proper distance and angle from the outside edge of the belt. When a belt drifts out of alignment it contacts the roller actuator arm which rotates the actuation shaft, causing the belt misalignment switch to send an alarm signal.

-

Rugged, heavy-duty design

-

CSA approved for Class II, Div 1 & 2, Group E, F & G applications

-

Accessories to suit your application

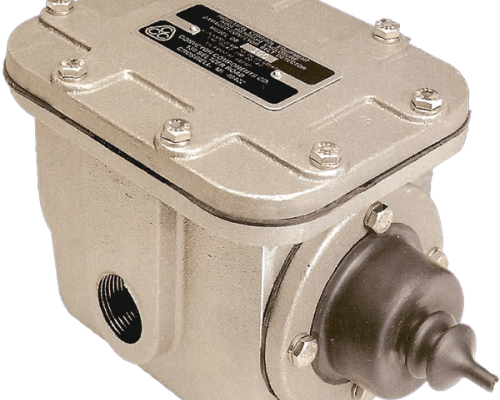

Safety Cable Pull Switch

This safety cable pull switch is used as an emergency shutdown device for conveyors or other equipment. They meet OSHA and MSHA requirements for safety shutdown devices.

Safety pull cables are attached to the actuating arm of the switch. When force is applied to the pull cable it rotates the actuating arm and actuating shaft. At a 20° rotation the switch enters a tripped and locked position. The actuating shaft has two cams inside the housing. Each cam simultaneously actuates an independent SPDT micro-switch for shutdown and alarm signals.

-

Meet OSHA and MSHA requirements for safety shutdown devices

-

Improved temperature spec for low temp applications

Tripper Position Switch

This tripper position switch is a heavy duty limit switch. It is often used to indicate the position of a tripper on a conveyor with multiple discharge points.

The actuating arm of the tripper position switch uses a large Acetal contact roller, 3 in diameter by 1.75 in wide. When the roller makes contact it rotates the actuation shaft which has two cams inside the housing. Each cam actuates an independent SPDT microswitch for position or alarm signals.

The switch can be ordered with an option where one of the SPDT switches is actuated with clockwise rotation and the other SPDT switch is actuated with counter-clockwise rotation. This allows you to identify which direction the switch is activated from.

-

Rugged, heavy-duty design

-

CSA approved for Class II, Div 1 & 2, Group E, F & G applications

-

Accessories to suit your application

Belt Rip Detection

Get an extra measure of protection for valuable conveyor belts with these new Damaged Belt Detectors.

Economical and easy to install, they warn supervisory personnel of impending belt failures due to

rips, punctures, splice failures, or sharp objects protruding through the belt fabric. It’s simple, effective, and it gives that extra warning of possible belt failure. But, even though the idea is simple, these detectors are not lightweights. They’re rugged, heavy duty units that are designed to work in any industrial environment including hazardous locations.

-

Easy to maintain

-

Cost effective

-

Installation ready

John Chandler & Associates Inc.

Thermo Ramsey & Ramsey Switches

A Certified worldwide distributor of Ramsey switches for dry and wet material handling operations.

© John Chandler & Associates, Inc. All rights reserved.

Built by Webfoot